By the editors of De Ondernemer

The biggest challenge in the mattress industry remains the waste problem. In the Netherlands alone, more than 1.5 million mattresses are discarded every year. The cause: barriers such as time, effort and costs for the consumer, the municipality and the producers themselves. Startup Ubed wants to do something about this.

Ubed's mission is to gradually tackle the waste problem in the industry, while giving customers the best night's sleep. The solution that the startup offers are modular mattresses made from 100 percent recyclable materials and a completely sustainable service.

Nowadays, only one third of all discarded mattresses in the Netherlands are recycled. A mattress that is in the bulk waste is only recycled if it is clean and dry, otherwise it is not even eligible for recycling. The vast majority of mattresses that are recycled are given a new life as an inferior product, also known as downcycling.

A judo mat or insulation material is then made from a mattress with a foam filling. In recent years, circular mattresses have come onto the market based on this idea, but in these initiatives the consumer remains responsible for the return shipment that must start this process.

A circular vision that does not stop at the product

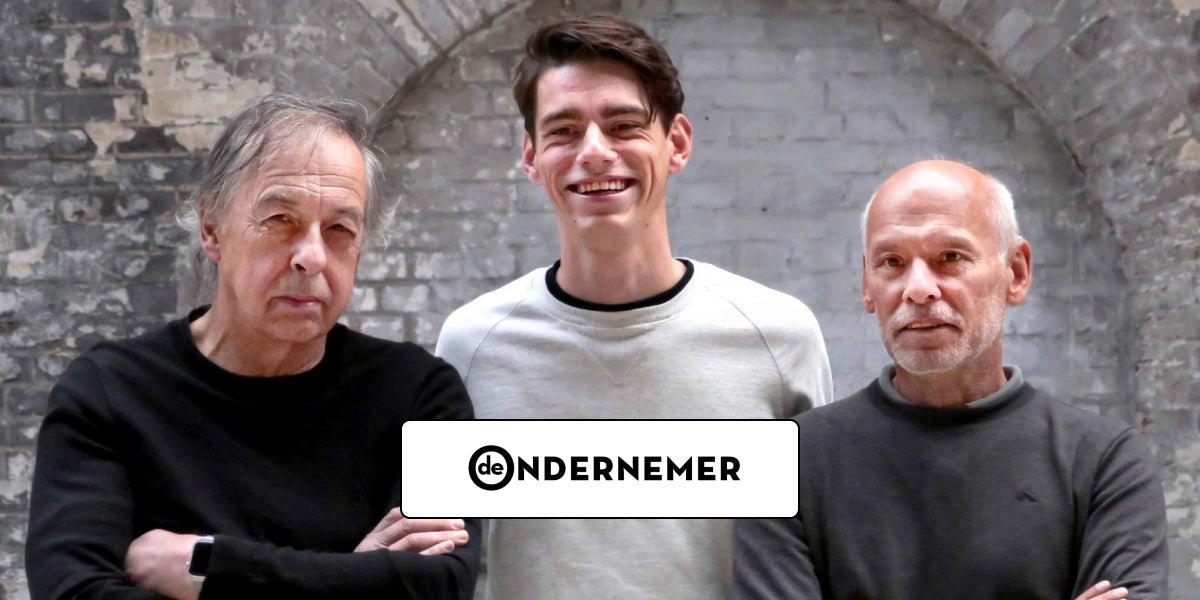

The idea of developing a mattress with a fully circular vision had been on the table for some time by Eduard Zanen, founder of Bugaboo, and Frans de La Haye, the designer of the iconic Auping bed frame. Auronde .

But it wasn't until the young, enterprising Wouter Simons (28) steps into Ubed that he really puts his weight behind it and the idea starts to take off. "In the development of our mattress, we have taken into account all problems within the industry, from product to service," says Simons.

A mattress with lasting value

The mattress is the first to use only high-quality polyester for the filling instead of traditional foam filling, the startup promises. All parts of an Ubed, from the glue to the top layer, are therefore easy to recycle and retain their value. "The modular construction makes parts such as the comfort layer interchangeable, which means Ubed can extend the lifespan of the mattress, as not every part in a mattress wears out at the same rate. This way, less energy and material is used over the years."

When the mattress is ready in many years, Ubed will collect the mattress itself using reusable transport covers to develop new mattresses. Simons: “In this way, Ubed guarantees circularity. The consumer will receive an appropriate reward from us for returning the mattress. This saves time, effort and costs for the consumer.”

How personal comfort should minimize returns

Furthermore, Ubed's goal is to prevent returns, because it is one of the major polluting components in the retail market. The hardness of each mattress is therefore determined per side based on the customer's weight, height and favorite sleeping position. Simons: "If the mattress does need to be adjusted, this can easily be done in the bedroom because the core and comfort layer are modular, so the mattress does not have to be returned."